Ball valve parts

We are specialists in the production of ball valve parts and are known for our ball valve seat assemblies: the absolute summit of a custom-made product. We compile this seat assy from multiple parts of different materials.

Our ball valve parts are used in the marine, offshore and chemical industries, as well as in transport and transshipment (specially for liquid transport and LNG transport) and other sectors.

Ball valve parts according to your specifications

Our extensive machinery is equipped with all the right tools for every solution. We produce ball valve parts according to your specifications. This can easily be done on the basis of a drawing or model. The table below provides an overview of the ball valve parts that we produce to measure.

Back up ring / ring support

Ball support disc

Body gasket

Body seal

Bonnet gasket

Chevron set (v-ring set)

End cap

Gland packing

Gland spacer

FFKM o-ring

Rear seal

Seat assembly

Seat / front seal / seat insert

Seat retainer / seat holder

Spiral wound gasket

Stem bearing

Stem bushing

Stem packing

Stem seal

Stem thrust bearing

Thrust washer

Trunnion bearing

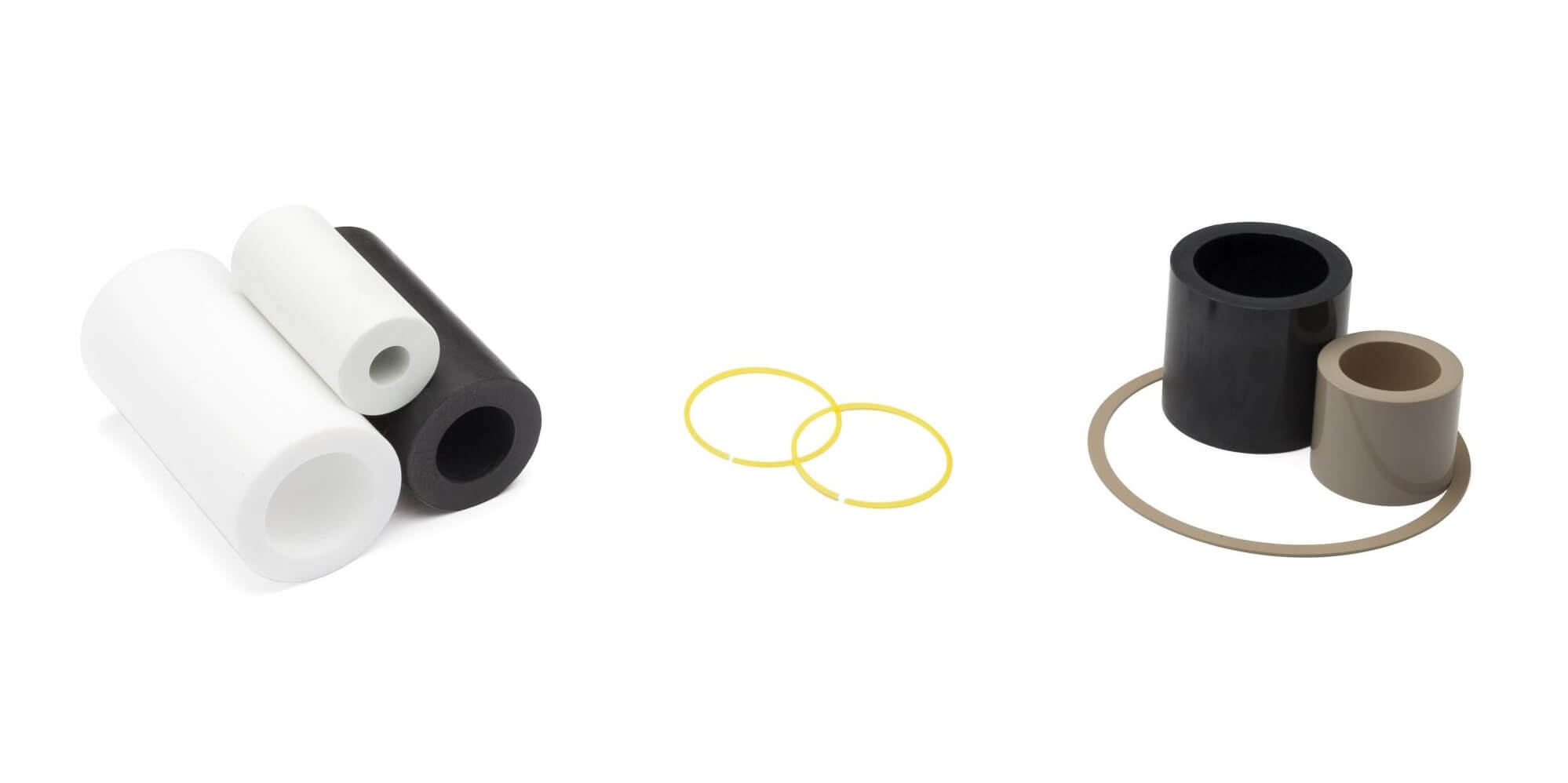

Ball valve seat assy

Our seat assembly always consists of multiple parts in different materials. Thanks to our years of experience, also of shrinkage and expansion of the different materials, fitting different parts into a seat assembly has become one of our specialties. Often metals are combined with graphite (hard or soft) and plastics. A seat assy is assembled in the following way:

- Ball valve seat (front seal / retainer)

- Ball valve retainer (zittinghouder)

- Ball valve seal (rear seal)

- Possible addition: o-ring or backup ring

Machining plastics or carbon graphite are very different specialisms than machining metals. Every plastic or graphite behaves differently under external factors. We machine all parts of the seat assy in-house. In our machine shop, we have specialists for turning metals, carbon graphite and plastics.

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.