24-05-2019

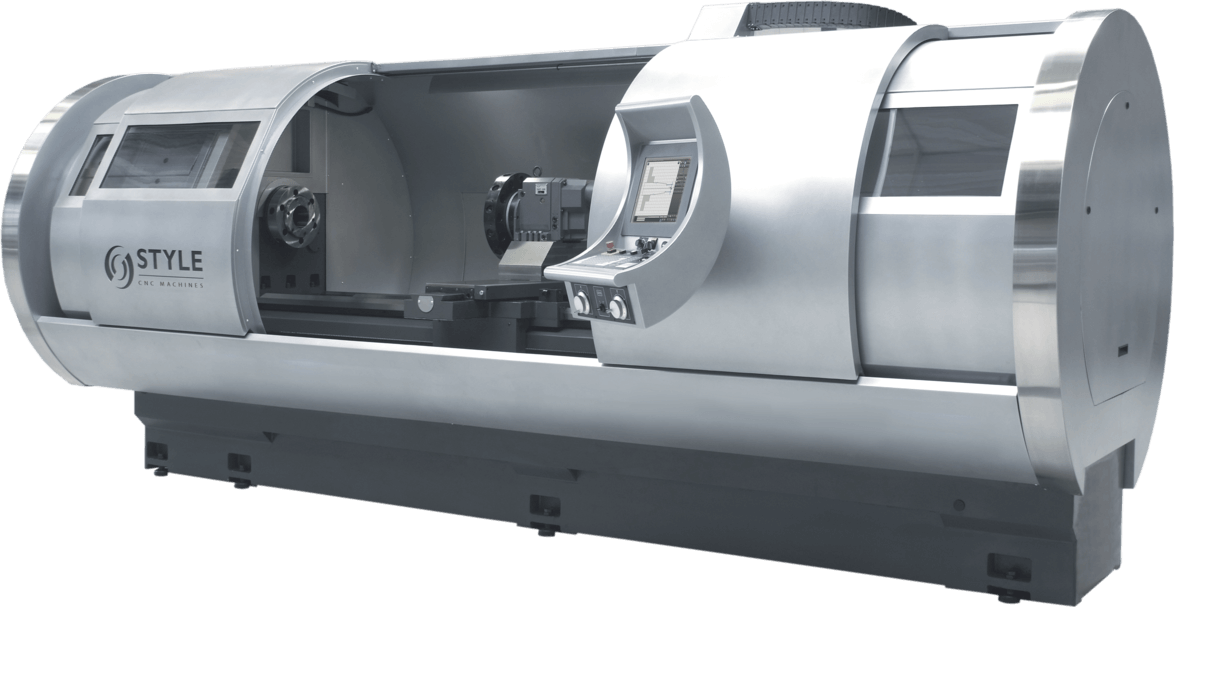

Bigger capacity CNC turning plastic due to style 660 lathe

Always nice to mention: our capacity for CNC turning of plastic and metal parts has been extended. We have supplemented our machinery with a Style 660 lathe for larger diameters.

This computer-controlled lathe makes plastic and metal products quickly and accurately. Of course with software that is completely up-to-date.

Style 660: Large turning diameter

Ridderflex already has a lot of CNC lathes in its turning shop, including the Style 510. The Style 660 provides extra capacity. But not just that: this lathe has a large turning diameter of 660 mm and measures 3000 mm between the centers. This means that extra large products can be CNC turned with this machine.

CNC turning metal

We will benefit from the new lathe when we produce seat assemblies with extra large metal retainers (seat holders). The seat assembly is perhaps the showpiece of Ridderflex, the absolute summit of a custom-made product for the valve industry. We compile the seat assy of multiple parts of different materials. Often metals are combined with graphite (hard or soft) and plastics. We turn the retainers from stainless steel, titanium, Nickel Aluminum Bronze, Hastelloy or Duplex ourselves.

CNC turning plastics

Of course Ridderflex will also machine large custom-made plastic products on the Style 660, such as seats and rings. Machining plastics is a very different specialism than machining metals. Every plastic behaves differently under external factors such as temperature and humidity. We guarantee a high level of accuracy in all turning. Depending on the material, we can work to tolerances up to 0.05 mm.

Turning and milling: our specialism

Over the years, Ridderflex has turned plastic turning into an art. If you are looking for a reliable specialist for plastic machining, at Ridderflex you are at the right place. We can turn all types of plastic. Ridderflex is especially strong in the production of customised products. We also manufacture products with complex shapes.

Do you want to have customised plastic products made in our turning shop? Please contact our sales department.