Polyurethane bearing pad

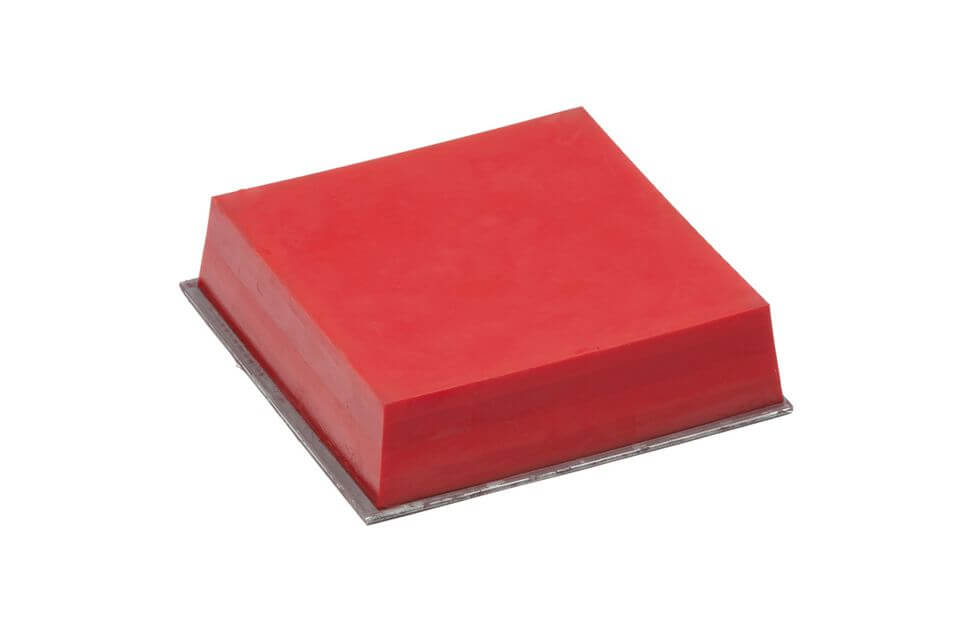

Our polyurethane bearing pad is an excellent alternative for all standard elastomeric bearings on the market. A polyurethane bearing makes the use of steel reinforcements redundant, while a higher load can be achieved.

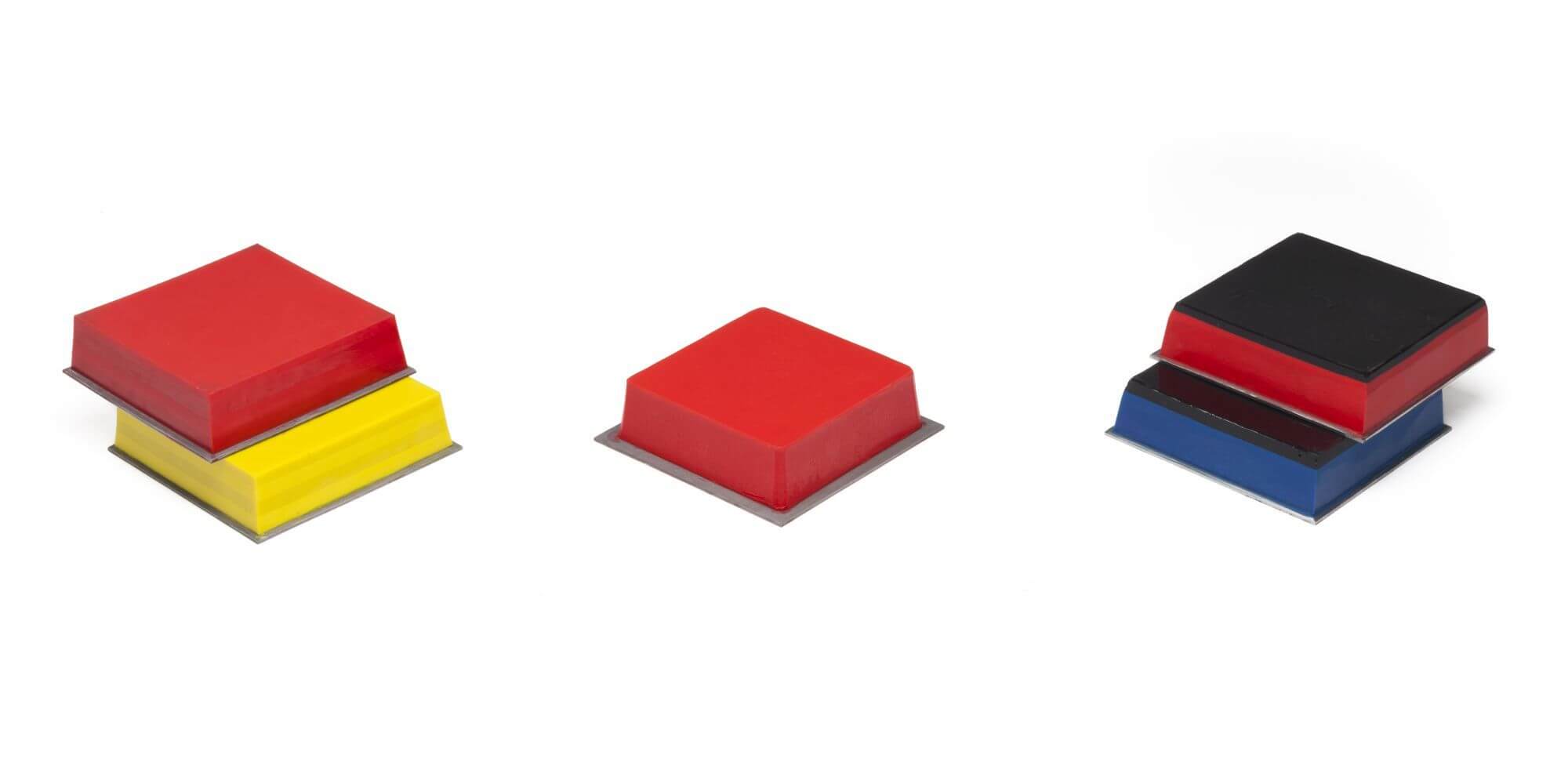

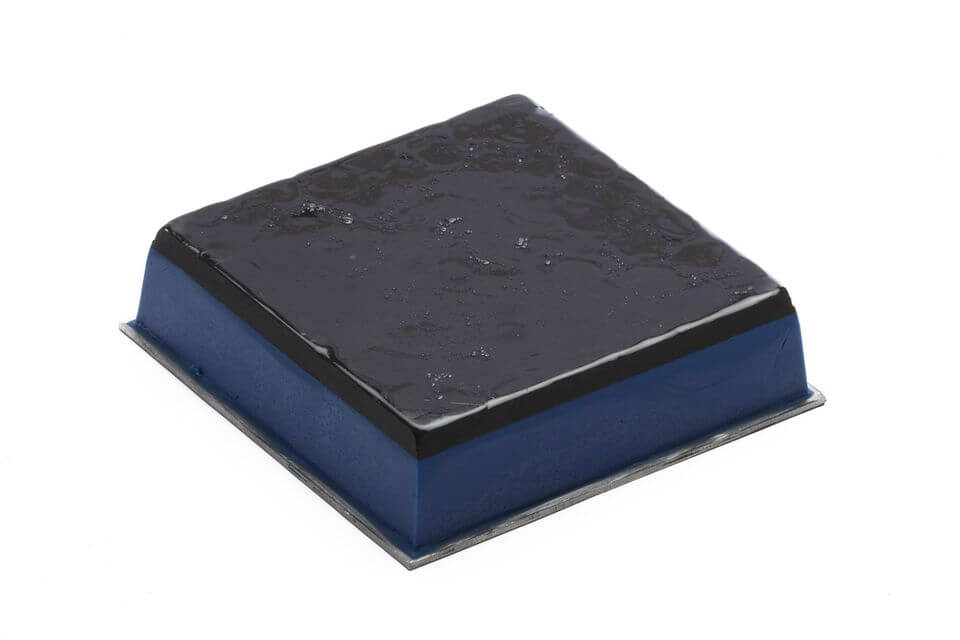

We can combine different hardnesses in one bearing. In that way, we can adjust our product perfectly to your application. Ridderflex manufactures polyurethane bearing pads in different hardnesses and colours.

Application of our bearings

Our polyurethane bearing pads are used amongst others in the construction of wind turbines, in the building and construction industry (bridges, tunnels and high-rise buildings) and residential construction. The bearing can be used for :

- collecting horizontal and vertical loads;

- countering rotations and

- absorbing deformations.

Ridderflex produces polyurethane bearings custom-made. For the wind industry we produced bearings that are used in the installation of a jacket platform. The bearing pads are used in this application in order to properly position the jackets and to absorb high loads during installation.

Properties of polyurethane bearing pads

Our polyurethane bearing pads have the following properties:

- Excellent ozone and UV resistance;

- Excellent resistance to aging;

- Seawater resistant;

- Excellent pressure levelling properties;

- Dimensionally stable;

- Wide temperature range;

- Low or high compression by combining different hardnesses and

- Resistant to mineral oils, gasoline, greases and various solvents.

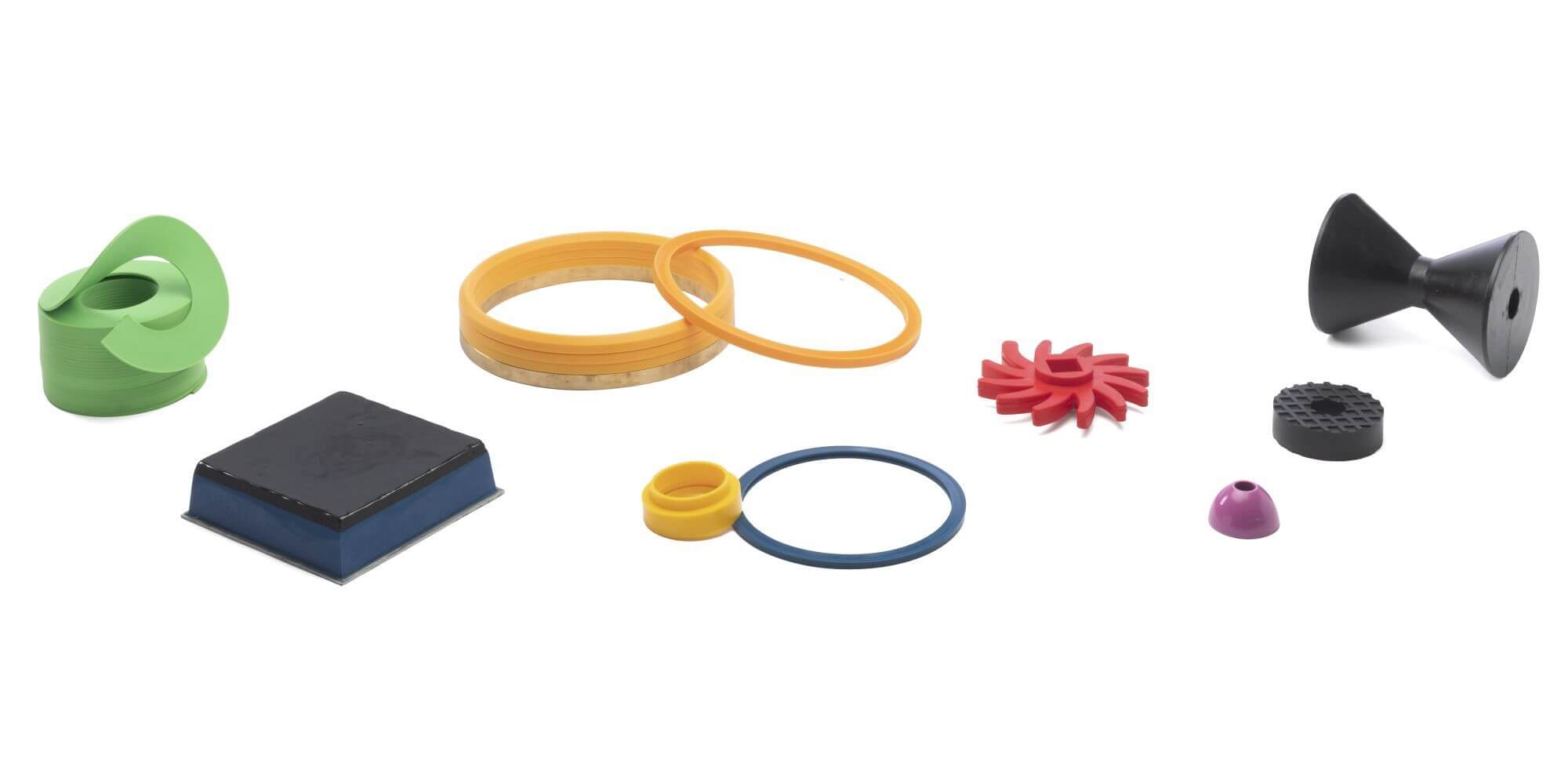

Bearings: various types

Ridderflex is a manufacturer of polyurethane, material is always available. That means that we can deliver quickly at an attractive price.

We can make our polyurethane bearing pads in different hardnesses and colours. Moreover, combining hardnesses into a single bearing is possible. In other words: multiple layers in several hardnesses Shore A and / or Shore D. A combination of materials can provide the required compression, pressure levelling and possibly lubrication. Ridderflex tunes the product to match your needs.

| Dimensions | Custom-made |

| Shape | Custom-made. Options include: square, rectangular and round shapes (beveled / descending, with rounded corners) etc. |

| Hardness | 20 Shore A to 95 Shore A 45 Shore D to 83 Shore D |

| Multiple layers | Combination of several hardnesses (laminated) in a bearing is possible. If desired, the bearing can also be provided with a sliding top layer (lubricating dimples optional). |

| Anchoring construction | PU bearing moulded on mounting plate or through threads. Various grades of steel possible. |

| Colour | Various colours available. Useful for identification. |

Our testing facilities for polyurethane bearings

Ridderflex has the facilities to test amongst others the compressibility, the load and shear modulus of the polyurethane bearings. Are you curious about our polyurethane bearing pad? Please contact us!

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.