Dock fenders

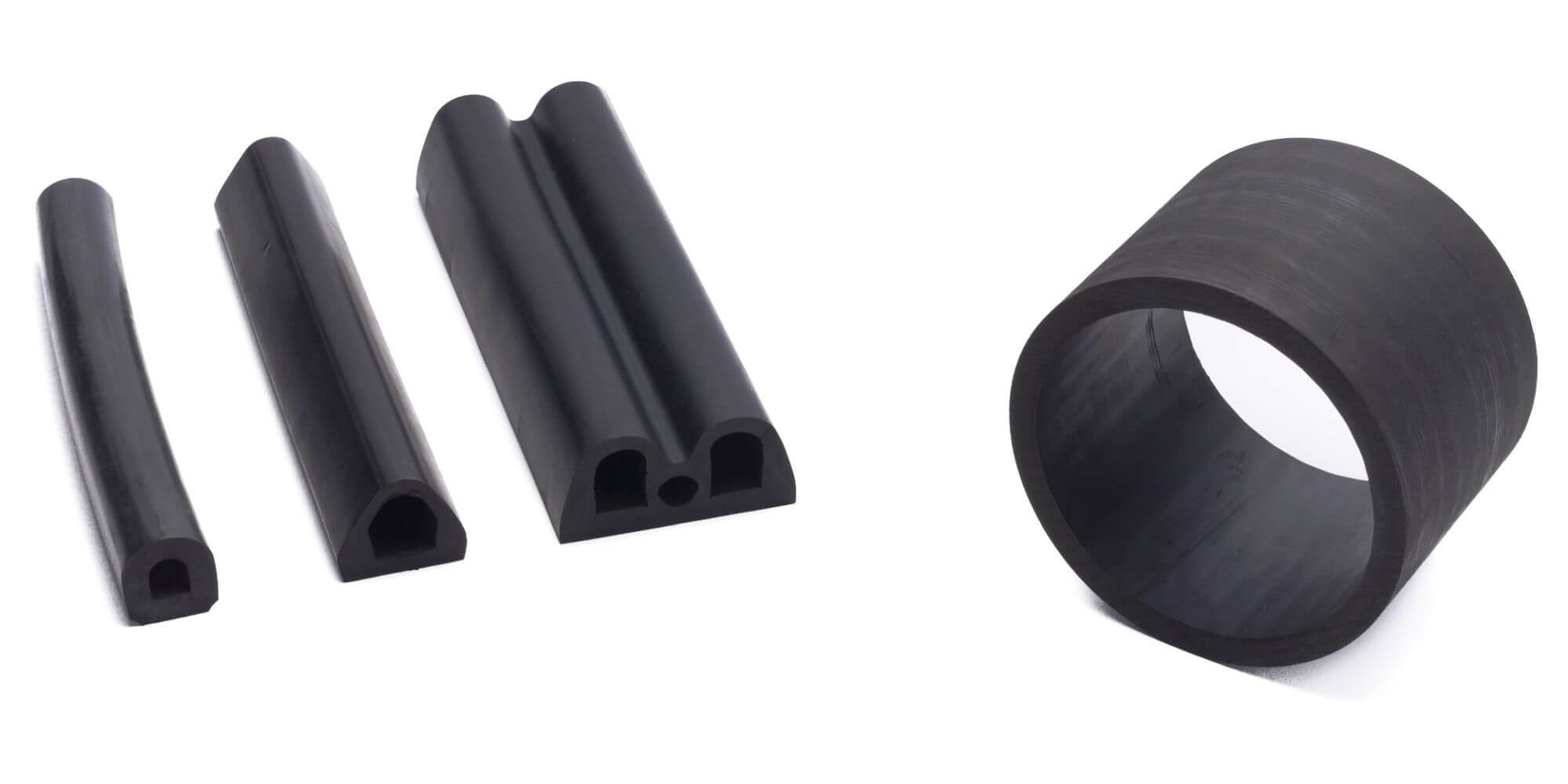

Are you looking for dock fenders? Ridderflex offers an extensive range of standard rubber fenders, amongst others: D fender, delta fender, wing fender, M fender and W fender. They absorb impacts and are used to protect amongst others ships, docks, loading docks, trucks and trailers. Also, Ridderflex supplies custom-made fenders.

Dock fenders (rubber) absorb impacts and are mainly applied to protect. The choice of material and shape is essential. If short delivery times are required, it is also possible to produce your fender in polyurethane (PU).

Custom-made dock fenders

We can produce your dock fenders custom-made. This can be done simply based on a drawing or model. In addition, the fender can be produced in the desired radius, so it can easily follow the contour of a bow or stern.

Various types of dock fenders / dock bumpers

We supply fenders in different types, materials, hardnesses and sizes. We supply the dock bumpers in the desired length. Angles can be glued or vulcanized. We are happy to advise you about all the possibilities. Please contact our sales department!

We supply various standard types of dock fenders:

- D fender

- Delta fender

- Cylindrical fender

- Keyhole fender

- M fender

- Square fender

- W fender

- Wing fender

D Fender

D fenders are the most commonly used dock bumpers. The D fender has a flat back, which makes it easy to install on various surfaces. This can be done by means of bolts and/or strips in various manners: horizontally, vertically or diagonally. Mounting holes are made through the top and bottom of the fender, or through the sides.

There are three different types of D fenders available:

- With an inner chamber, D-shaped;

- With an inner chamber, O-shaped;

- Solid, without an inner chamber.

Delta fender

The delta fender is easy to install and has a minimal contact surface. Mounting holes are made through the top and bottom of the fender. A properly mounted delta fender is able to absorb high levels of energy because of a relatively large inner chamber.

Cylindrical fender

Cylindrical fenders absorb forces and loads. These rubber dock bumpers are simple to install. These can be mounted horizontally, vertically or diagonally using chains or rods.

Square fender

A square fender is used when a more rigid and stronger bumper is required for use in heavy duty applications and the D fender does not comply.

Keyhole fender

A keyhole fender absorbs large forces. These dock fenders are usually mounted vertically with fixing pins through the two standard holes on the bow of a vessel or the wall of a quay as a dock bumper. The keyhole fender can be produced with an UHMPE surface layer.

M fender

The M fender has a wide and flexible contact surface. The M shape provides flexibility. Therefore, it can easily follow the contour of a bow or stern. The M fender is often installed vertically with the help of fixing pins through three standard openings.

W fender

The W fender is used to absorb excessive shocks and impacts in extreme conditions. That is why this type of fender is used on the bow and stern of tugboats, workboats and icebreakers. This fender is often attached vertically with fixing pins through the two standard holes.

Wing fender

The wing fender is usually mounted on the inside of a profile, which creates a dock bumper that is highly resistant to all kinds of forces. This type of fender has an o-shaped inner chamber (standard), but can also be produced without an inner chamber (solid).

Question? Enquiry?

We excel in the production of custom-made plastic, rubber and polyurethane products.