17-10-2019

Advantages of plastic parts compared to metal

Metal (machine) parts are often the easiest and most trusted choice. But plastic parts often offer more options. In some cases these products are even a better or cheaper alternative than the traditional metal product.

Ridderflex is happy to explain why. In this article we will also list a number of our plastic alternatives to metal products.

5 advantages of plastic

Perhaps you have never considered that your (machine) parts can also be made in plastic. And that plastic parts might be much more interesting than traditional metal products. We are happy to show you our top 5 advantages of plastic compared to metal. Plastic parts:

- are usually better chemical resistant

- are often self-lubricating (no lubricants required)

- sometimes have a substantially lower cost price than metal

- have a lower frictional resistance

- are lighter in weight.

Plastic parts alternative to metal

Which plastic parts are a good (or even better) alternative to the traditional metal product? We list a number of plastic alternatives of Ridderflex and show you the advantages:

Bearing bush

The standard metal bearing bush has no good chemical resistance and always needs a lubricant. Advantages of plastic bearing bushes: They are good chemical resistant and self-lubricating. Plastic can be used as an alternative in 90% of the applications. (psst: PTFE bushings are suitable for the food industry (FDA)).

Sleeve bearing

Plastic flanged sleeve bearings have a high load and are wear resistant. So far no big difference with metal sleeve bushings. But they excel in chemical resistance, are suitable for the food industry (FDA) and the material is often self-lubricating. Choosing plastic is almost obvious.

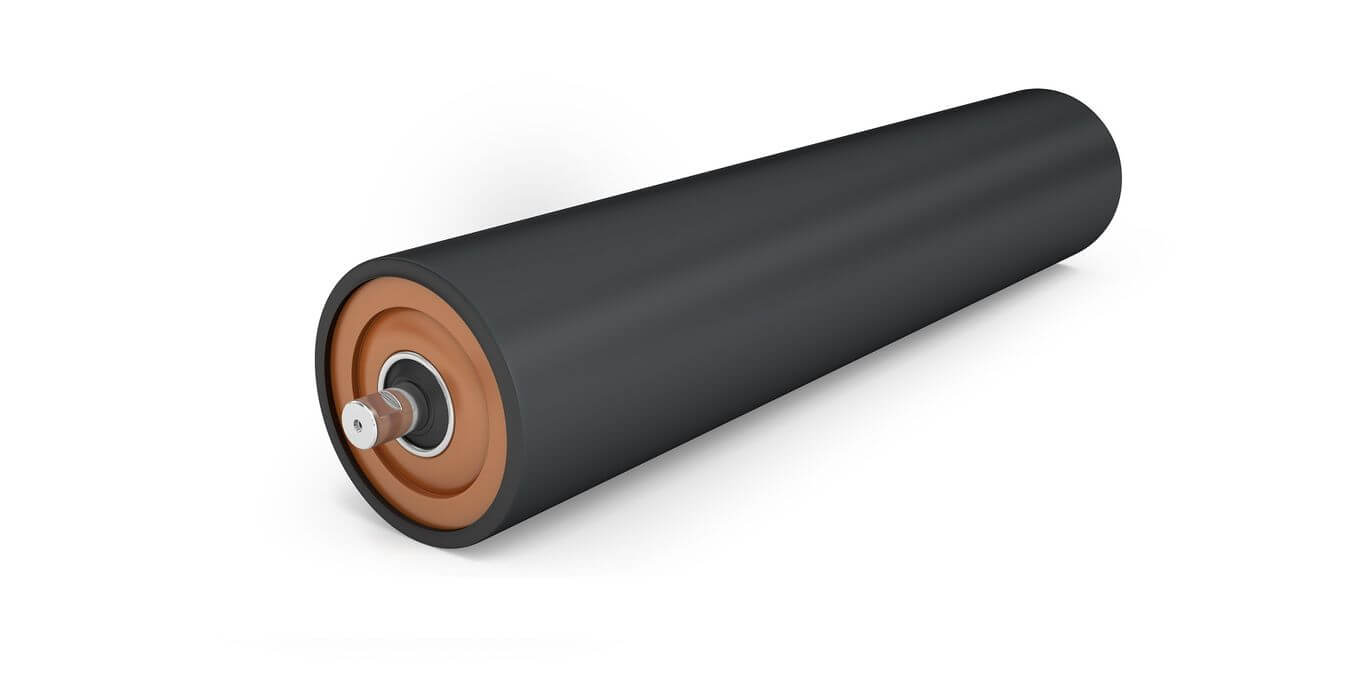

Track roller

The traditional roller bearing is often made of (cast) steel. However, plastic can be an interesting choice, because a self-lubricating roller is quite practical. A steel part is not always (easy) to lubricate. Plastic rollers also have enough resilience to quickly return to their original shape.

Slide guide

Without a lubricant, wear occurs on metal guide profiles. Lubricants are not required with a plastic chain guide. Advantages of plastic: The material has optimum running properties (much quieter than metal!) and a very high wear resistance.

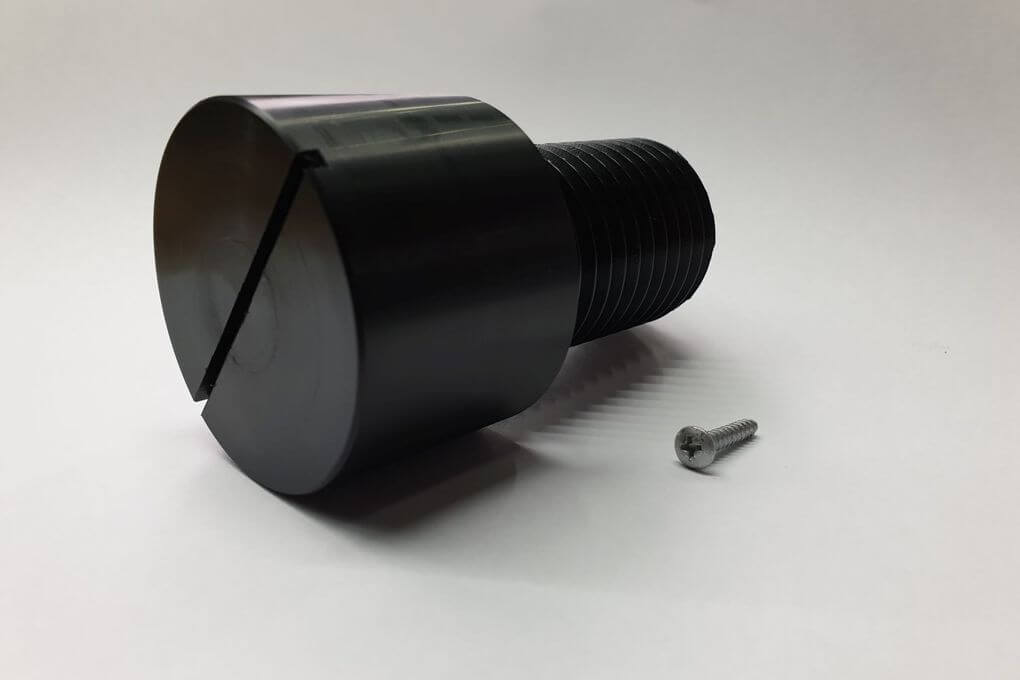

Bolts and nuts

These are usually available in (galvanized) steel as standard. But what if they have to be mounted in an acid or aggressive application? Then they are corroded by the acid or medium or, worse, worn away. In this case it is better to choose for plastic bolts and nuts.

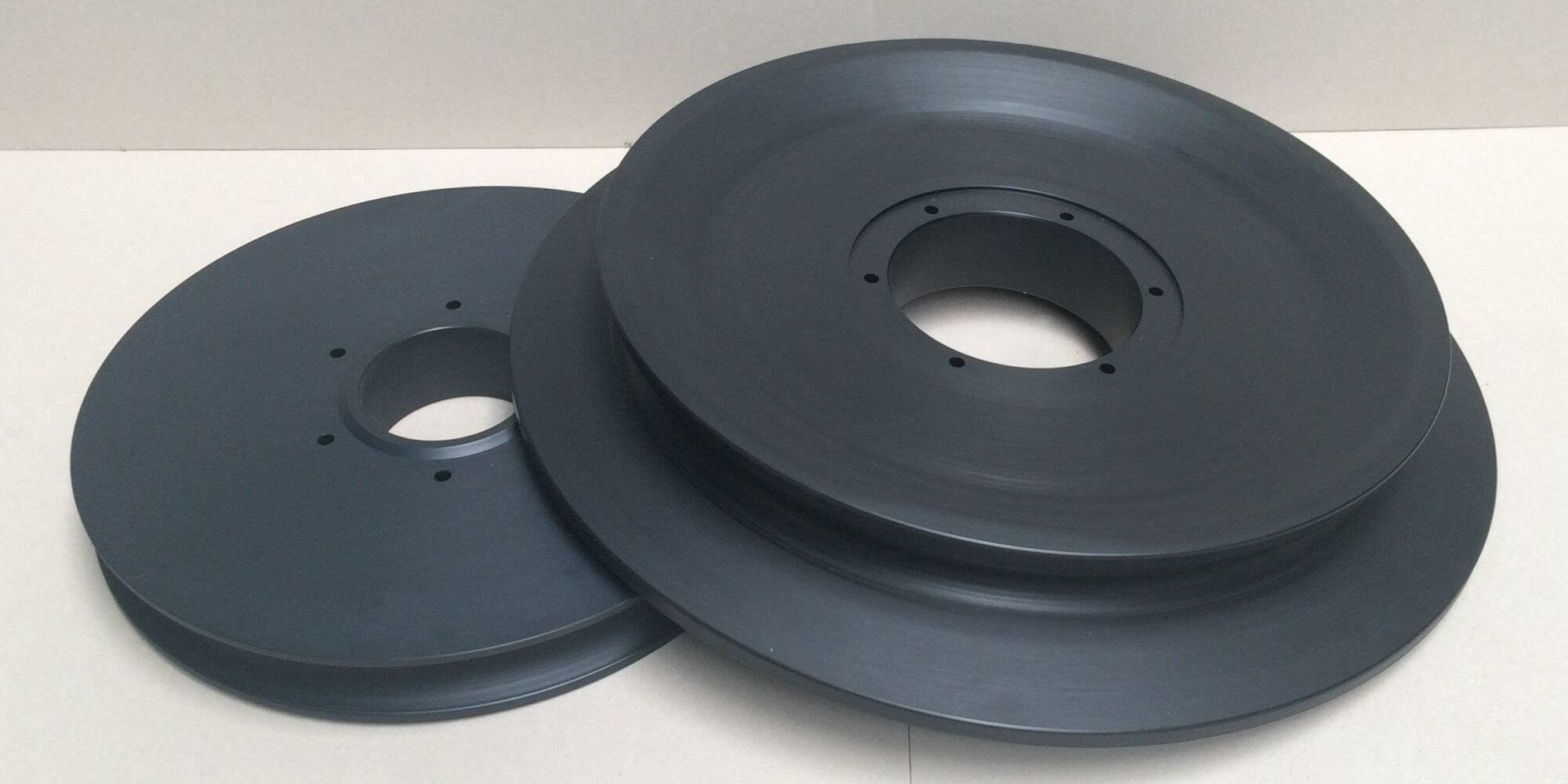

Sheave wheel

We can mention several advantages of plastic with the cast polyamide (PA6G) sheave wheel compared to a steel sheave. One: A longer cable life. Two: They are about seven times as light as a steel version. This eases the handling and assembly of the sheaves.Three: Due to the good damping properties of the material, vibrations running noises are reduced.

Even more alternatives to traditional products

Do you want to see even more alternatives to traditional products?. We developed polyurethane bearings as an alternative to all rubber-steel variants on the market. And our PU rotor blades are perhaps a better product than the existing alternatives on the market. That tastes like more… keep an eye on Ridderflex!