26-09-2017

Custom-made elastomeric bearing pad for seaway heavy lifting

‘Can you make an elastomeric bearing pad that meets our strict requirements?’ With this question Seaway Heavy Lifting approached us recently. They indicated that the product had to be used for the installation to 84 wind turbines of the Beatrice Offshore Windfarm Ltd project (UK, Scotland). As standard rubber-steel variations on the market did not meet the required values, Ridderflex offered a custom-made polyurethane dampening pad.

Ridderflex looks beyond standard materials and products. We always go the extra mile. We therefore suggested to our customer to use an alternative material for the elastomeric bearing pad: polyurethane.

Development of a new product

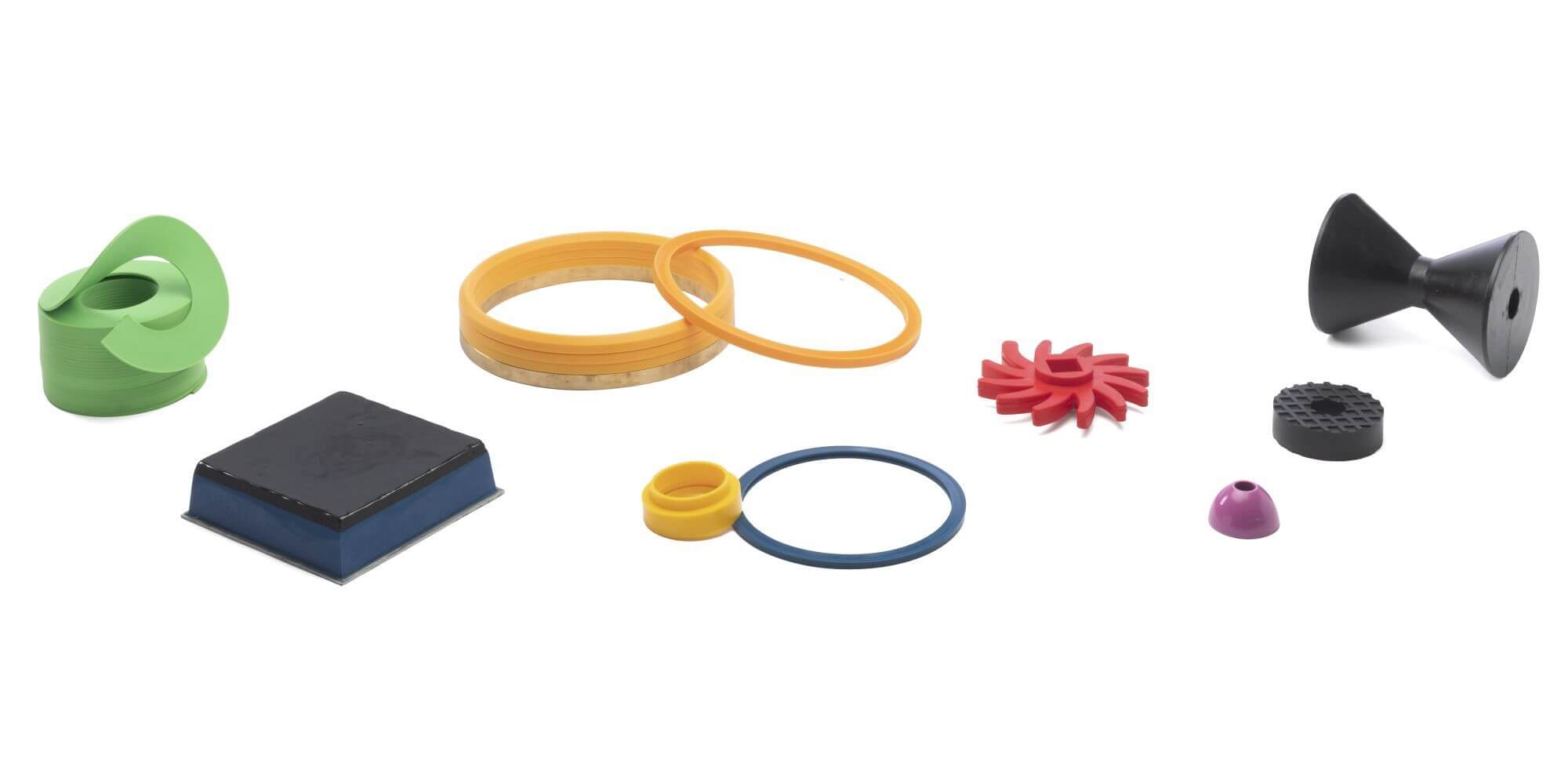

Polyurethane has the strength of plastic and the elasticity of rubber. It is a very versatile material. Ridderflex suggested developing a polyurethane dampening pad. A polyurethane bearing allows higher loads without the use of steel reinforcements. Also, different hardnesses can be combined in one pad. Together we developed a brand new product: a custom-made, on a steel plate moulded, elastomeric bearing pad (polyurethane dampening pad). By using external testing and modelling facilities to prove suitability under high velocity impact, the proposed material was found to be suitable for the intended use.

Custom-made elastomeric bearing pad

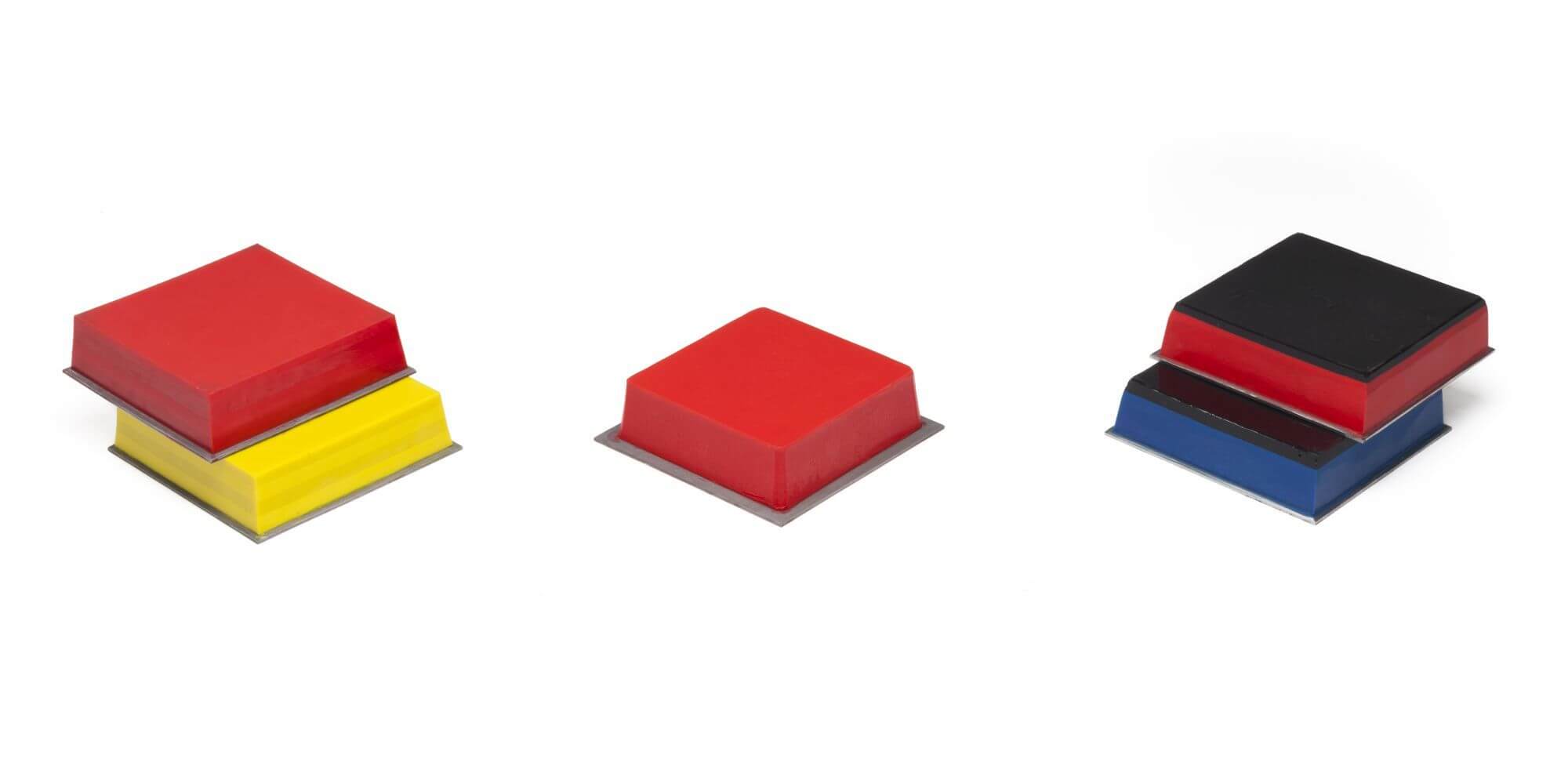

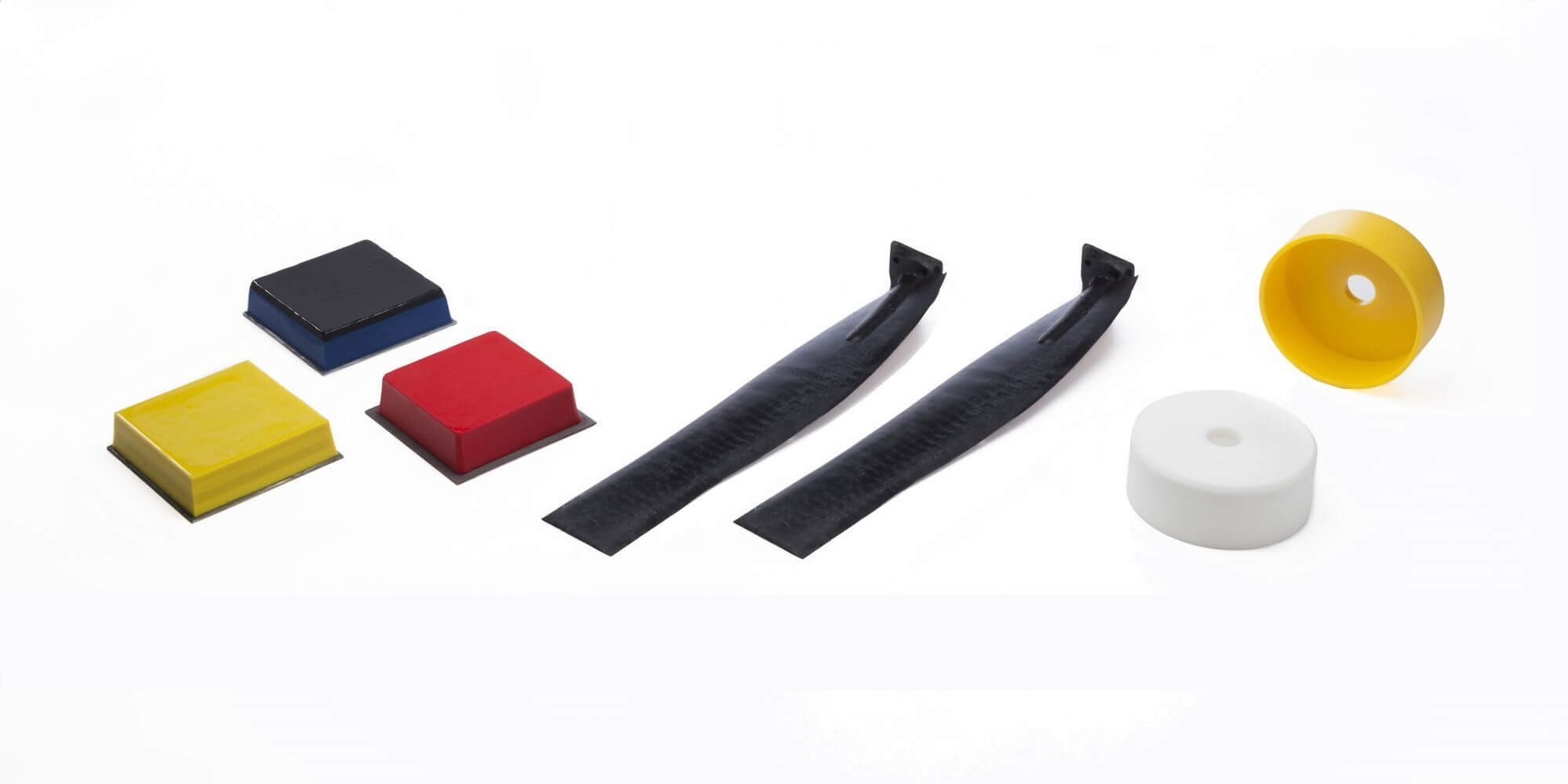

We can make our polyurethane bearing pads in different hardnesses and colours. Moreover, combining hardnesses into a single bearing is possible. In other words: multiple layers in several hardnesses Shore A and / or Shore D. A combination of materials can provide the required compression, pressure levelling and possibly lubrication. In that way, we could tune the product to match the needs of our customer.

Essential when installing wind turbines

In a short period of time Ridderflex supplied thousands of customised elastomeric bearing pads (polyurethane) moulded on a steel plate to Seaway Heavy Lifting. They were integrated in the jacket pile grippers for the installation of 84 wind turbine substructures on preinstalled foundation piles of the Beatrice Offshore Windfarm Ltd project in Scotland.

About Beatrice

The £2.6bn Beatrice Offshore Windfarm Ltd (BOWL) project has been given the green light for construction by owners SSE (40%), Copenhagen Infrastructure Partners (CIP) (35%) and Red Rock Power Limited (25%) after reaching Financial Close on 23 May 2016. The project will be one of the largest private investments ever made in Scottish infrastructure.

We are proud to have participated in this great project. Thus, contribute to cleaner and more sustainable wind energy: one of the main power sources for the future.